TECHNOLOGY

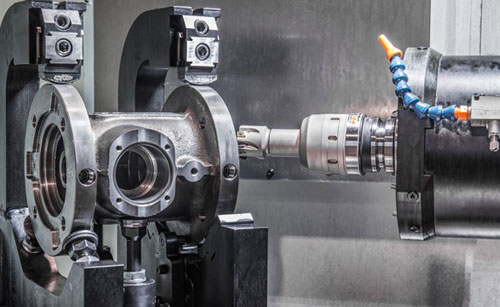

Machining

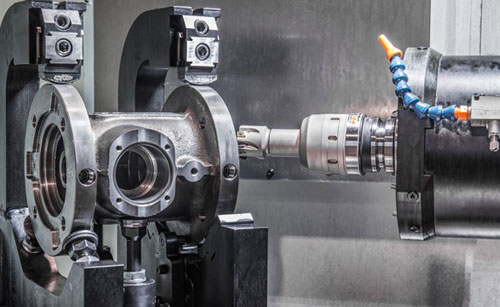

The aim resulting from the pursuit of an extensive customer service is to offer a highly processed casting – a finished product for the customer’s assembly line. That is why our offer includes machining, which we outsource to our partners. We perform mechanical treatment on our own and in cooperation with other Machining Plants.

Painting, packaging, shipping

Painting of castings is carried out on two lines – Adal immersion line and robot-assisted immersion and spray line. At the customer’s request, we deliver castings: primed, surface coated with water-based polyurethane, epoxy, alkyd, phthalic, styrene-based paints, in any color, powder coated. Packaging according to the customer’s requirements, e.g. film-wrapped castings on pallets, in disposable wooden boxes, on EUR pallets, in UIC pallets, etc.