TECHNOLOGY

Machining of castings

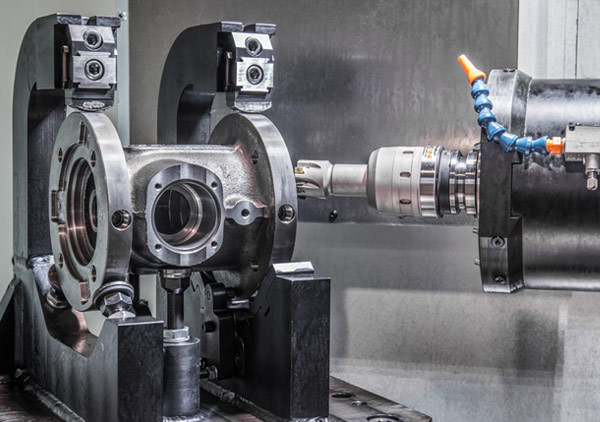

Our aim, through extensive customer service, is to offer a highly processed casting – a finished product for the customer’s assembly line. That is why we also offer machining, which we outsource to our partners. We perform our own mechanical treatment and in cooperation with other machining plants.

Around 90% of the machining of castings is carried out in CNC centers. We process castings with the dimensions of the HWS and LORAMENDI moulding lines.

We use NX CAD/CAM machining computer-aided manufacturing systems to design castings.

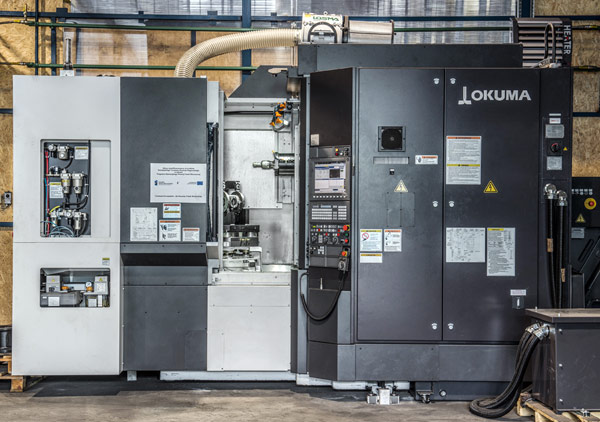

Our CNC machine tools:

- FMS Fastems

- OKUMA MA-400HA horizontal machining center: two-pallet CNC machine tool for machining small and large production batches; manufactured in 2014, Japan

- OKUMA Genos L400 turning center; manufactured in 2013, Japan

- Three HP5-16 machining centers; manufactured in 2002, Poland; shift in axes: X 860mm, Y 700mm, Z 650mm; spindle speed 2900 rpm; two pallets with dimensions 630 x 630mm