TECHNOLOGY

Forming castings

The process of forming castings is carried out on automatic Loramendi moulding lines (the vertical type, with the variable moulding chamber) and Maschinenfabrik Heinrich Wagner Sinto (horizontal moulding lines).

LORAMENDI

| Type of moulding machine | Type of machine | Dimensions of moulds [mm] | Production volume | Casting weight [kg] |

| Automatic vertical moulding line and variable moulding chamber | LORAMENDI VMM5070C | 600x480x300 675x550x300 |

Medium and high volume | 0,5÷25 |

The line contains:

- pMC and SBC mould conveyors with a total length of over 60m,

- QPC quick pattern plate change unit,

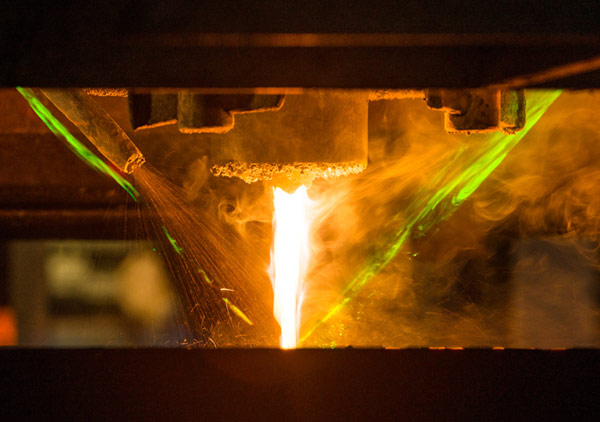

- CS core insertion unit,

- a device for pouring “pourTECH” – a cold chamber ladle of 1500 kg with a temperature measurement on the stream and laser-controlled stopper.

HWS

| Type of moulding machine | Type of machine | Dimensions of moulds [mm] | Production volume | Casting weight [kg] |

| Automatic moulding machine, horizontal type | EFA – SD4 | 800x650x300/350 | Medium and high volume | 15÷150 |

The line contains:

- pourTECH pouring unit – a 1400 kg cold chamber ladle with temperature measurement on the stream

- automatic robot for puncturing vents and inserting core boxes

- the ability to manually pour metal from the ladle